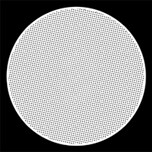

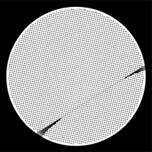

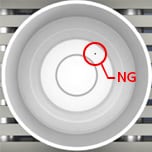

Key inspection points

DPF (diesel particulate filter) or catalyst workpieces are large in size, which makes it difficult to perform appearance inspections for defects such as cracks and clogs. However, by using a 21 megapixel camera, which has the highest pixel count in the industry, it is possible to perform highly accurate inspections.