Solve a Variety of Measurement Challenges with a Single System

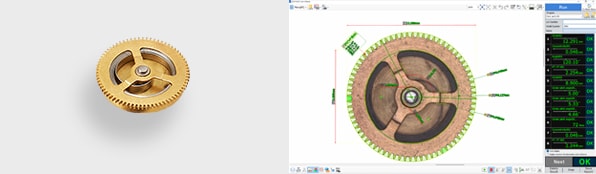

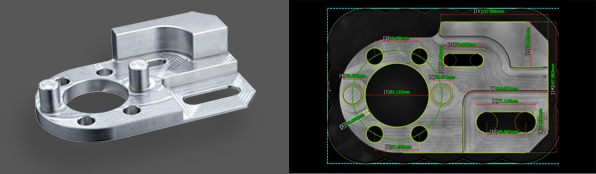

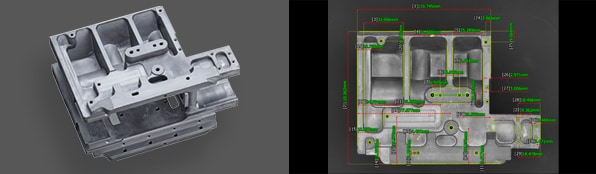

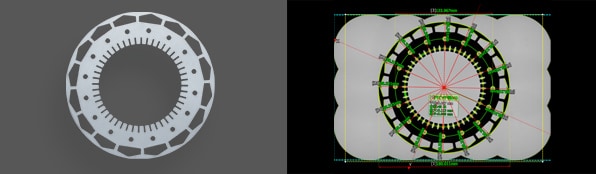

No need to orientate or focus your parts.

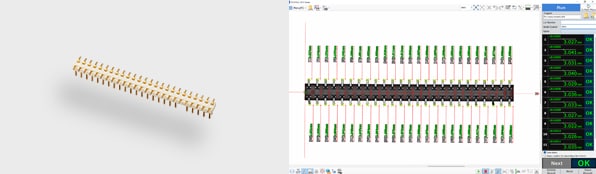

The speed and ease-of-use of this product makes it possible to measure up to 5000 points on up to 1000 parts at the same time, drastically reducing the measurement time.

Conventional models

LM-X Series