Thickness / Width

When selecting sensors to measure thickness or width, the first step is to choose a method. The target's material, colour, and location will all play factors in which option is the best fit for your application. You can browse through the most common setups below, or request a free consultation with a local measurement expert.

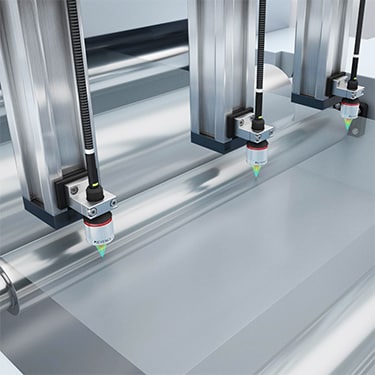

A sensor is placed above and below a target to measure the thickness of anything in-between. This non-contact method can be used for measuring the thickness of any material and can be used in process or for offline inspection.

Confocal Displacement Sensor

CL-3000 series

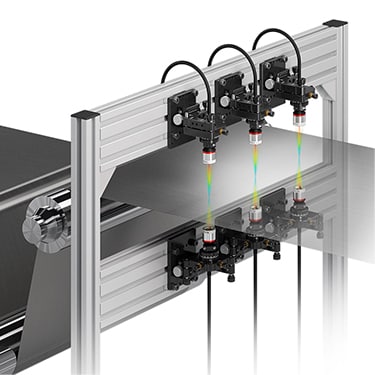

Opposing 2D profilers can scan multiple points of thickness over a part. This allows stable thickness measurement even on rough surfaces.

2D/3D Laser Profiler

LJ-X8000 series

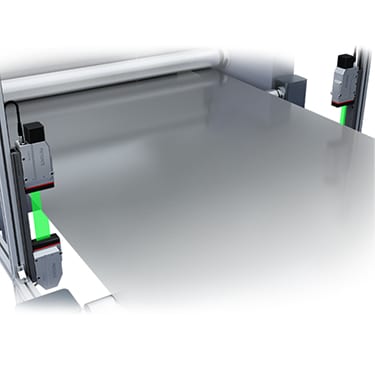

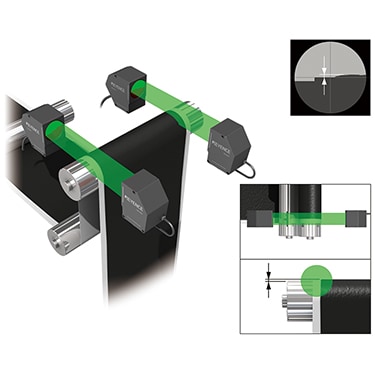

With two thrubeam micrometres installed on either side of a film, we can get a width measurement and give film position, regardless of colour or material.

High-speed optical micrometer

LS-9000 series

2D thrubeam sensors can measure the step height between a roller and a sheet to get a thickness measurement. Additionally, A second sensor can be added to get a width measurement.

High-speed 2D Optical Micrometer

TM-3000 series

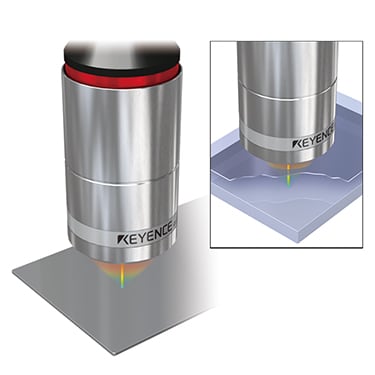

Measure transparent films and coatings with a single displacement sensor. Confocal sensors give an accurate thickness measurement from one side of transparent targets.

Confocal Displacement Sensor

CL-3000 series

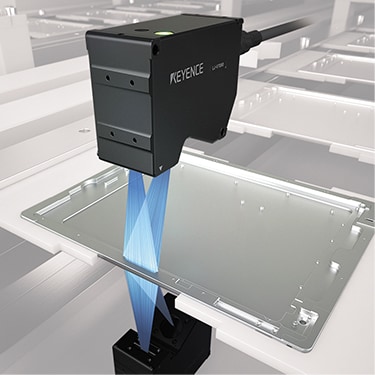

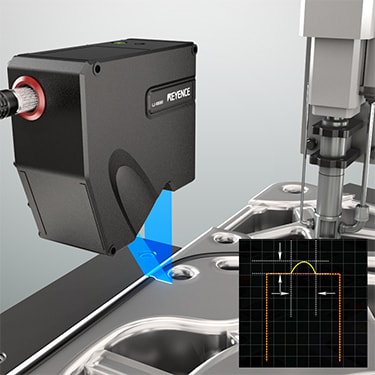

2D Profilers give width, height, and volume of sealant beads inline without touching a part.

2D/3D Laser Profiler

LJ-X8000 series

Conventionally, a vision sensor was used for OK/NG judgement based on the area. Since the LJ-X8000 Series can measure the volume and position of paste application, it can reduce material costs and support higher component densities.

2D/3D Laser Profiler

LJ-X8000 series

In-line thickness measurements of thickness changes caused by roller eccentricity, wrinkles or tension changes are possible. Up to 6 measurement points and 4 layers of clear film can be measured with a single controller.

Confocal Displacement Sensor

CL-3000 series