Quantifying Evaluation with Automatic Measurement and Analysis of Particle Shapes

Particle materials are used in the products in various industrial fields. To evaluate the performance of particles and to understand their physical properties, it is important to know not only their diameters but also their shapes. To that end, it is necessary to quantitatively measure particle shapes at production sites where particle materials are used so as to appropriately manage the quality and performance of products and the manufacturing processes themselves.

This section explains the purpose of measuring particle shapes and their typical parameters. It also introduces an example of using our 4K digital microscope to automatically measure particle shapes.

- Purpose of Measuring Particle Shapes

- Particle Shape Measurement Parameters (Circularity, Aspect Ratio, and Enveloping Degree)

- Particle Shape Measurement Method

- Example of Automatic Measurement and Analysis of Particle Shapes

- A 4K Digital Microscope That Quantifies and Speeds Up Particle Shape Measurement and Evaluation

Purpose of Measuring Particle Shapes

Typical product fields targeted for particle shape measurement and physical characteristics evaluated by these measurements are as follows.

| Product field | Physical characteristic evaluated |

|---|---|

| Food |

• Texture |

| Pharmaceuticals |

• Powder fluidity in drug delivery system (DDS) |

| Product processing and treatment |

• Grinding efficiency of abrasives (SiC, etc.), tools, etc. |

Particle Shape Measurement Parameters (Circularity, Aspect Ratio, and Enveloping Degree)

Circularity is the typical parameter for particle shape measurement, but aspect ratio, and enveloping degree (convexity and solidity) are also commonly used. These parameters, important in measuring and evaluating particle shapes, are explained below.

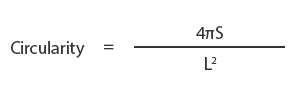

Circularity

This is the most commonly used parameter in particle shape measurement. In general, it expresses how close a particle is to a perfect sphere. One example of its use is in evaluating the abrasive characteristic of abrasive particles.

Assuming that S is the projected area and L is the circumference, this parameter is calculated with the formula below. A circularity of 1 indicates a perfect sphere. The more complex the shape, the smaller the circularity becomes (smaller than 1).

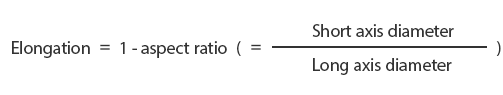

Aspect ratio and elongation

The aspect ratio is the ratio of the lengths of two of the following axes: X, Y, and Z. It is used to differentiate between particles having different dimensions along one axis such as needle- and egg-shaped particles and between spherical and square particles.

Assuming that a is the short axis diameter of the particle and b is its long axis diameter, this ratio (a/b) can be determined. The elongation, which indicates the length and narrowness of the particle, is 0 when the aspect ratio is 1, such as for circles and squares. The elongation is calculated with the formula below.

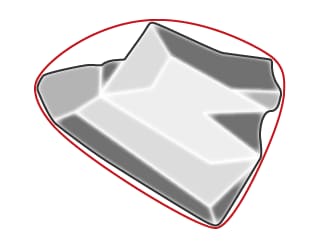

Enveloping degree

This parameter is used when detecting aggregated particles and when evaluating surface roughness. Sometimes, even though actual particles have complicated shapes, evaluation does not require the detailed shape of each particle. Enveloping degree makes evaluations easier by somewhat simplifying the surrounding shape.

To calculate this parameter, use the enveloping perimeter, which can be thought of as the length of an elongated rubber band temporarily stretched around the outline of the particle and is also called the particle perimeter (edge contact surface).

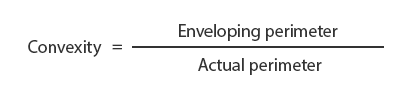

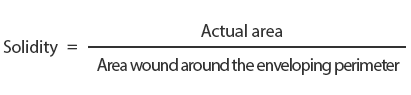

From this enveloping perimeter, the following formulas can be used to calculate the convexity and solidity.

The smoother the outline of the particle, the closer the enveloping degree and the solidity approach 1. On the other hand, the enveloping degree and the solidity are smaller than 1 in the case of aggregated primary particles and particles with rough outlines.

The next section will explain how to acquire the measured values required to calculate these parameters.

Particle Shape Measurement Method

The general method for measuring particle shapes, which are three dimensional and complicated, is to use image analysis that converts a magnified image of the particles into a two-dimensional projection drawing.

Binarisation (2D binarisation) is the image processing applied to the image of the particles. The measured values of the particle shapes are acquired and the features of the parameters required for evaluation are calculated by extracting the optimal information for the intended analysis.

What is binarisation?

It is processing that converts an image having multiple shades into one having two colours. Within the specified range, the value of each pixel is compared against thresholds to sort the pixel into one of two categories.

Applying binarisation to an image makes it possible to extract just the necessary information from the required part, allowing for easier and faster particle shape measurement and calculation.

Image analysis during particle shape measurement

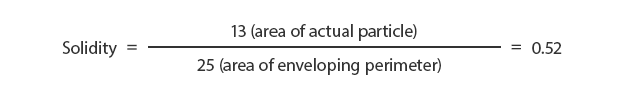

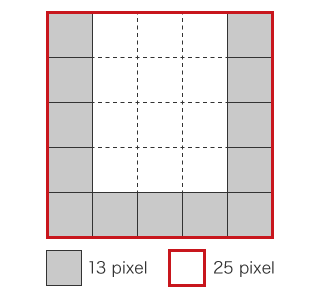

This section uses the measurement and calculation of solidity, one of the particle shape measurement parameters, to explain image analysis.

This simple diagram shows an example of finding the solidity by performing binarisation according to pixels. The following value can be calculated by defining 13 pixels in the image as the area of the actual particle and 25 pixels in the image as the area of the enveloping perimeter.

Read on for an application example of our 4K digital microscope, which easily realises quantitative evaluation by acquiring clear, 4K images and by utilising intelligent automatic measurement and analysis functions.

Example of Automatic Measurement and Analysis of Particle Shapes

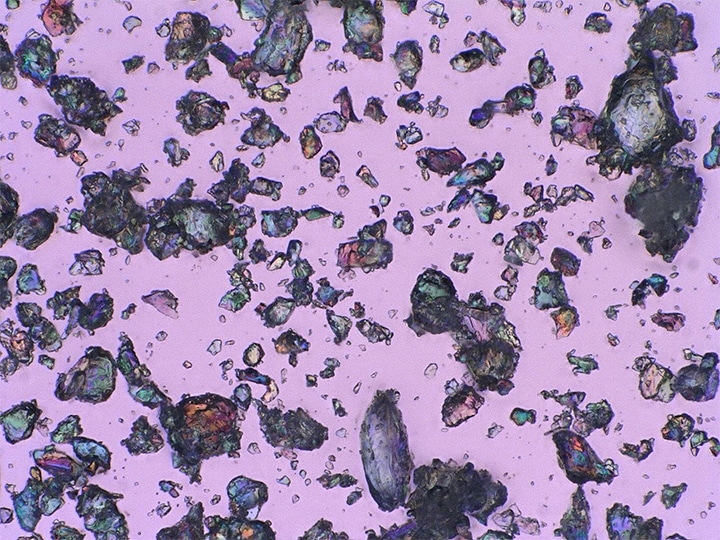

To acquire accurate measured values from images of particles, it is first necessary to capture clear, magnified images of particles with a microscope under optimal conditions. It is also necessary to calculate highly reliable parameters by consistently measuring the shapes of the particles, of which there are many in the field of view.

However, it is extremely difficult to determine conditions and to focus on the targets when capturing images of particles, so the operator must be very proficient and have a high level of technical skill. Even for highly experienced operators, it is difficult to measure overlapping particles.

KEYENCE’s VHX Series 4K digital microscope is equipped with an advanced optical system and motorised hardware, enabling the acquisition of the clear images needed for accurate particle analysis. The observation system, which provides various functions accessible with simple operations, strongly supports analysis work. The function that automatically analyses the acquired 4K images allows advanced measurements, which are difficult to perform, to be carried out easily and quickly.

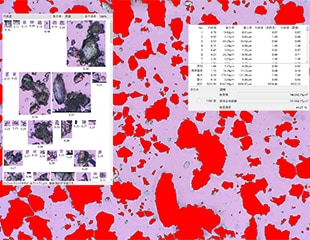

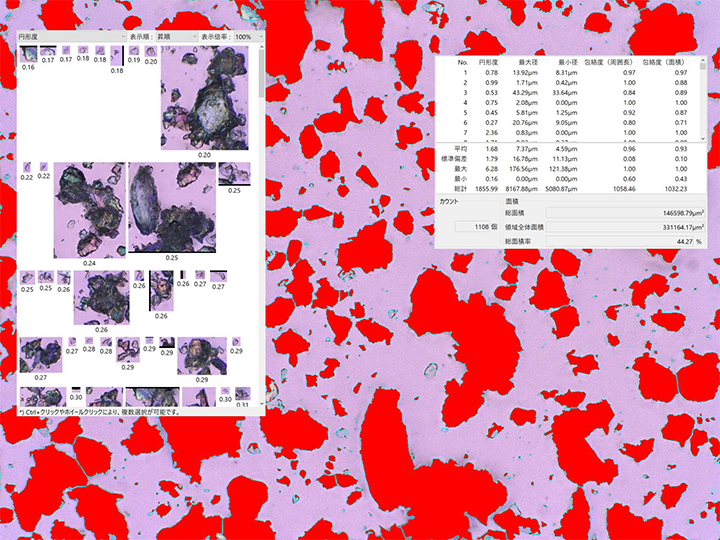

An example of using the VHX Series to acquire clear, magnified images of particles and to automatically measure and analyse the particle shapes is introduced below.

Automating and optimising particle shape measurement and analysis with a 4K digital microscope

The VHX Series 4K digital microscope uses an optical system, a 4K CMOS image sensor, and an original observation system that combine high resolution with a large depth of field. High resolution 4K images can be acquired easily, avoiding false detection and misidentification and enabling accurate measurement and analysis.

Although determining the lighting conditions requires a long time, this requirement can be reduced with the Multi-lighting function, which automatically acquires the data of multiple images captured under omnidirectional lighting at the press of a button. Just visually select the image matching the purpose to quickly start observation and analysis. Additionally, when a past image is selected, the conditions used to capture that image are reproduced, enabling measurement and analysis under the same conditions even for a different sample and a different operator.

The automatic area measurement/count function can be used for seamless automatic measurement and analysis of the particles in the area selected in the acquired image. This function not only accurately counts the number of particles but also automatically measures and calculates sub-micrometre level detailed values such as circularity, maximum diameter, minimum diameter, convexity, and solidity as well as their average, standard deviation, maximum value, minimum value, and total and displays these values in a list.

Applications include calculating the aspect ratio from the ratio of the maximum diameter and minimum diameter and acquiring the solidity of each particle with high accuracy by using high-contrast images.

A 4K Digital Microscope That Quantifies and Speeds Up Particle Shape Measurement and Evaluation

The VHX Series 4K digital microscope quantifies evaluations by enabling smooth and fast acquisition of clear, 4K images and automatic measurement and analysis with simple operations.

Additionally, Excel can be installed directly on the VHX Series to automatically create reports by outputting values and images to templates. Seamlessly carrying out the series of work from magnified imaging and measurement/analysis of particles to report creation, this product greatly optimises particle measurement work.

For additional info or inquiries about the VHX Series, which strongly supports particle shape measurements, click the buttons below.