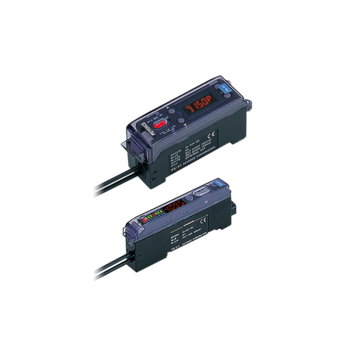

Manual-Calibration Fibreoptic Sensor

FS-V/T/M series

Recommended Replaceable Products: Digital Fibre Optic Sensor - FS-N40 series

Contact Us: +32 (0) 15 281 222 Enquiry form

Manual-Calibration Fibreoptic Sensor FS-V/T/M series

FS01 series fibre optic sensors and Tough-Flex optical fibres offer an extraordinary range of performance benefits.