Electrostatic Meter / Static Fieldmeter

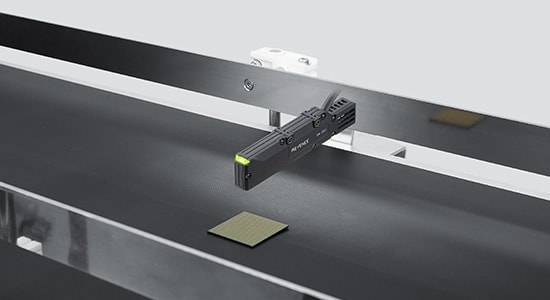

A static electricity sensor that accurately measures electrostatic charge to identify and diagnose locations with static build-up. A hand-held type—which can measure nearly anywhere—and an in-line type—which can measure the electrostatic charge of targets on a manufacturing line—are available.

Products Lineup

The major advantage of inline electrostatic sensors is that they can be installed in manufacturing lines, allowing for continuous real-time measurement of the electrostatic charge of targets. Conventional temporary measurement cannot detect problems caused by static electricity. One such example of these problems is a decrease in yield rate. However, real-time monitoring makes it possible to prevent these problems, contributing to improved manufacturing efficiency. This sensor can also improve quality management and traceability using measurement data, allowing it to respond to the advanced needs of manufacturing sites.

Features

Reasons Why Real-Time Monitoring of Target Electrostatic Charge is Required

Entry-level hand-held types are often chosen as the first tool for quantifying static electricity. Although capturing general trend values is possible with these sensors, monitoring conditions such as high-speed moving targets, environmental changes between morning and evening, or abnormalities during setup changes is more difficult. Even if inspections during equipment installation or maintenance pass, there are an increasing number of cases where yield issues—likely caused by static electricity—do not improve. Real-time measurement can dramatically enhance manufacturing efficiency for advanced devices.

Before

General trend value management with a hand-held measuring instrument

After

Continuous measurement with an inline measuring instrument

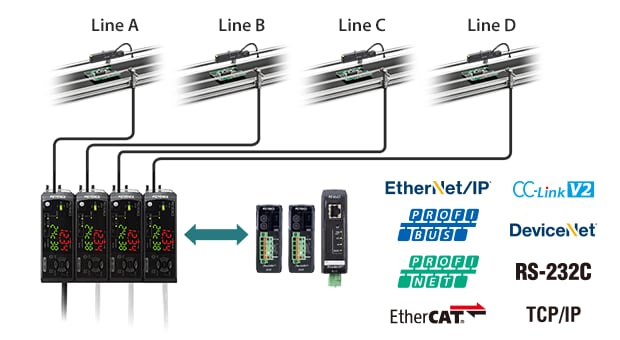

Easily Provides Visibility of Collected Data on Various Communication Networks

Standard specifications include an independent 3-output judgement system and analogue voltage/current output to collect and output the static electricity volume of the target as well as the temperature and humidity data of the surrounding area. By using a communication unit, data from up to 8 connected main units and expansion units can be transmitted simultaneously. The ability to read data and re-write settings from PCs and PLCs contributes to a significant reduction in man-hours required for setup and operation.

KEYENCE’s hand-held type electrostatic sensor is widely used as an entry-level model for quantifying electrical charges of static electricity. It can also measure temperature and humidity, making it possible to comprehensively understand the relationship between environmental conditions and static electricity. In addition, it can evaluate the static elimination performance, such as speed and ion balance, of ionizers. In this way, this sensor promotes the effective operation and maintenance of ionizers while also helping prevent static electricity problems. This hand-held sensor allows for flexible measurement in any location, giving it the major advantage of supporting diverse needs in on-site applications.

Features

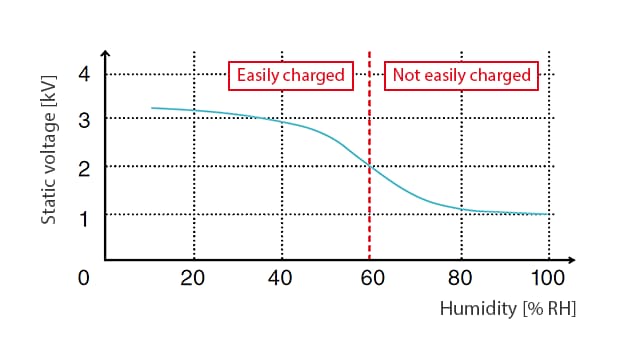

STATIC ELECTRICITY + HUMIDITY Simultaneous Measurement

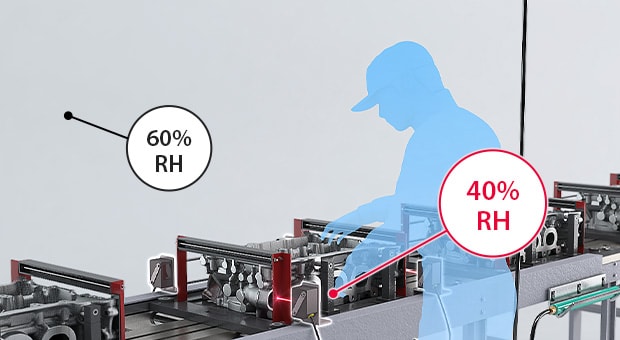

Measuring static electricity and humidity simultaneously makes it possible identify likely areas of static-related problems, paving the way for optimal static electricity solutions.

In addition, the humidity in the "area around the equipment" may be lower than that at the "room edge" because of the higher temperature. If static electricity problems persist despite humidity control throughout the room, checking the humidity "around the equipment" may help to resolve the problem.

Relationship between humidity and static charge (typical example)

Example of different humidity between the edge of a room and near the equipment

Determines the Static Elimination Performance and Deterioration Over Time of an Ionizer

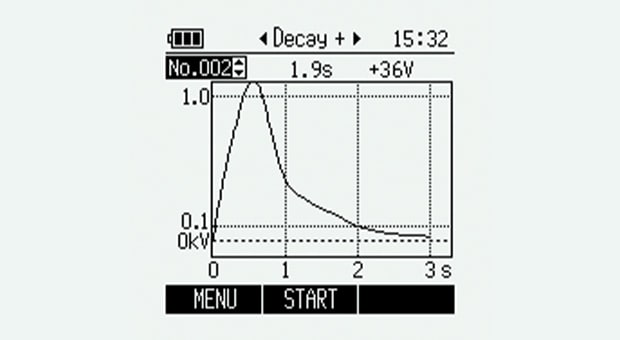

The SK-H050 features a charge monitor function that measures static elimination speed and balance, both of which indicate an ionizer's static elimination ability.

* Required ionizer monitoring unit SK-H055 sold separately.