Air-Free High Speed Sensing Ionizer

SJ-H series

Air-Free High Speed Sensing Ionizer SJ-H series

Removal of Static Electricity from Entire Rooms High-Speed Static Elimination without Air

The Air-Free High Speed Sensing Ionizer SJ-H Series can provide high static elimination performance even without utilizing air. This makes it the optimal device for situations where static elimination is required but no air can be used. To meet a variety of static elimination needs, the lineup includes a model with clean pack specifications and a silicone probe model. This ionizer can be used in a wide variety of applications.

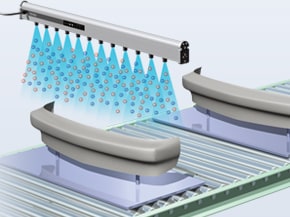

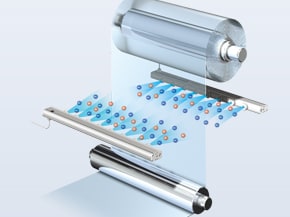

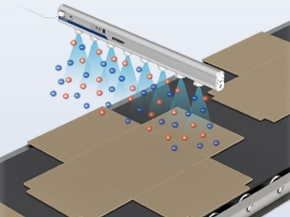

Applications

Features

High-Speed Static Elimination with No Air Flow

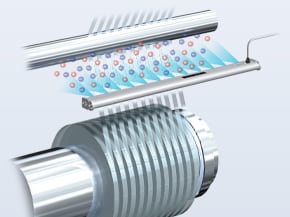

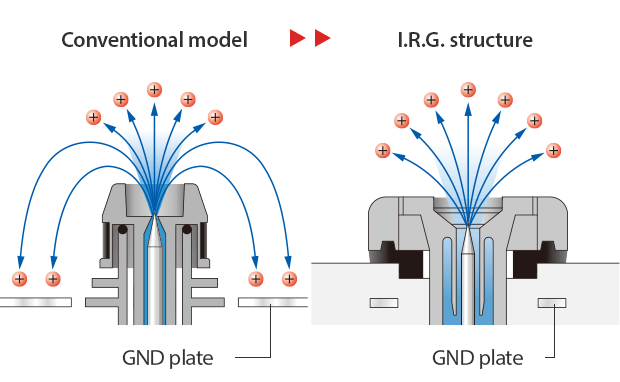

I.R.G. structure for air flow-free high-speed static electricity elimination

In conventional models, the GND plate essential for ion generation is mounted externally. KEYENCE's SJ-H Series, however, is the first to adopt the I.R.G. (Insert Ring Ground) structure, which includes the plate inside the ionizer. By directing the generated ions to the target rather than the GND plate, loss is minimised and the number of ions applied to the target increases. This allows for high-speed static elimination five times faster than conventional models.

High Usability

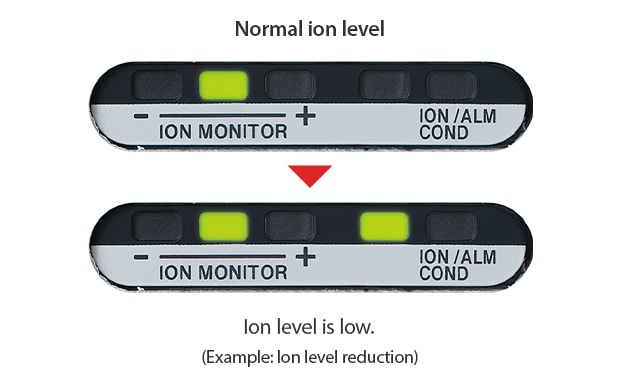

The SJ-H Series includes a self-diagnosis function that monitors the ion generation level. With the bar LED and alarm outputs, the ionizer alerts you when maintenance is required.

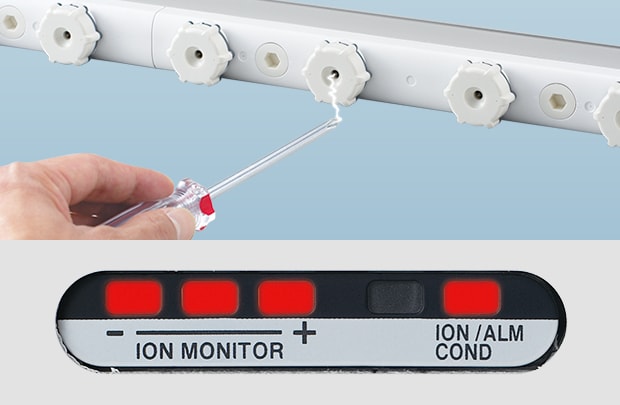

3-Way Alarm Output

The SJ Series provides the self-diagnosis function that monitors three types of abnormalities. If an abnormality is detected, the LED indicators identify the error condition and an external output is activated. Centralised control of ionizers is enabled by monitoring the external output.

[Cleaning warning]

Monitors reduction in ion generation level due to dirt or wear of the electrode probe.

[Condition warning]

Monitors a high charge level that cannot provide a sufficient static elimination effect.

[Alarm warning]

Monitors abnormal discharge or damage to the ionizer.